Sander-polisher Type SP-4/300-1330×3/Px2

Machine is oriented for doing sander-finish works in the lacquer process, wax coating, oiling, etc., especially wooden and wooden derivative elements with compound surface shape. Machine tool owns shafts, which can be equipped in inputs from rich assortment of abrasive materials and cleaning brushes which allows to do every finish works from sanding to cleaning. It is equipped in roller holding down system, useful especially with working small and light elements. Shafts with abrasive bearing pad and conveyor owns fluently speed regulation. Machine owns a system of regulation spindle high also, which allows on intensity of sanding and polishing treated elements.

SPECYFIKACJA TECHNICZNA:

- Conformed with CE safety standard,

- Voltage supply = 400V / 230V/ 50Hz,

- Total electric power = 16,5 kW,

- Overall dimensions: length=2500 mm, width =2200 mm, height = 2000 mm

- Belt conveyor in machine (length x height) = 2500 mm x 1300 mm,

- Sanding units optimum rotary speed = 100 ÷ 600 obr./min.,

- Conveyor speed : 5 ÷ 15 m/min. (or other after agreement),

- Exhaust / dust pull off – spindle heads: 3 x 1750 m³/h (by air speed 27 m/s),

- Exhaust / dust pull off – lateral spindle belts: 2 x 2000 m³/h (by air speed 27 m/s),

- Exhaust / dust pull off – axial-flow fan: 1 x 5200 m³/h (by air speed 27 m/s) – for 100% vacuum power,

- Working height = 850 ÷ 950 mm,

- Vacuum system – axial-flow fan 7,5 kW for elements with min. dimension 270 x 200 mm,

- LCD steerable panel with possibility to adjust all parameters and list of alerts and announcements,

- Free setting position of steerable panel from outrigger arm,

- Independent height regulation system:

- adjustment of table mechanism height depended on workpieces thickness,

- adjustment of sanding heads height depended on degree of abrasive inputs consumption,

- Workpiece thickness safety beam,

- (4 pcs.) Pressure rolls

- Electric equipment and automatics of Schneider Electric,

- Electrical protect system PREVENTA,

- Air recirculation system compatible with ISO 14001,

- Standard machine colour: construction – RAL 5015, door – RAL 7035,

- 12 months guarantee,

# Abrasive tools for sander-polisher Type SP-4/300-1330×3/Px2

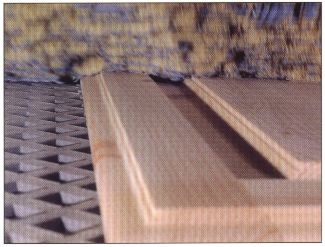

(3 pcs.) Abrasive heads ø140 / ø 300 / 1330 putted perpendicularly to the transport axis

according to specification below:

- Aluminium frame – spiral system of keys under brushes,

- Set of 72 abrasive segment inputs (agave’s horsehair + abrasive cloth) for fix in the head,

- Inputs length: 1330 mm; Inputs hair height: 70 mm,

- Granulation inputs within the range of selection: P 60 ÷ 400,

- Width incision of abrasive cloth: 4, 7 or 20 mm – accurate penetration of profiles treated material,

(2 pcs.) Transverse sanding belts with set of abrasive inputs

- Granulation inputs within the range of selection: P 60 ÷ 400,

- Inputs length: 80 mm; Inputs hair height: 70 mm,

- Width incision of abrasive cloth: 4, 7 or 20 mm – accurate penetration of profiles treated material,

EXTRA OPTIONS:

– Machine adjustable for work in technological line,

- Pneumatic turbo dust nozzle system,

- De-ionisation unit for unload electrostatic charge from dust

MACHINE ACCESIBLE ALSO IN 1000mm WORKING WIDTH!!!

This post is also available in: Polish